The Valve Gate Systems PDFs

Components made by the use a Valve Entrance normally have the least frozen-in tension, with no sprue, and also no visible defects - valve gate systems. Shutoff Gates can generate constant shot-to-shot repeatability, faster cycle times, great automatic mold and mildew operation as well as bulk high quality. Valve Gated mold and mildews are for that reason, ideal for automated high quantity manufacturing.

MDi's Single-Cavity Valve Gates feature the exact same cutting-edge gating innovation made use of in our multi-cavity Hot Runners. Stack molding needs much less room Uses smaller sized devices, which causes minimized run costs Generate two times as many components without raising press size/tonnage Raised outcome effectiveness Fewer devices called for Numerous component designs created concurrently Save money and time by producing several parts simultaneously Minimized waste A Heap Mold takes advantage of Newton's 3rd law of motion, in that the opposite pressure required to infuse a single face is now utilized to mold a second collection of components.

MDi provides Valve Entrance Heap systems in any type of arrangement to make sure that the customer accomplishes the maximum tooling remedy for their application. MDi offers top quality, high performance systems that also long lasting and reliable, provided in a timely manner, competitively priced as well as function MDi's cutting-edge nozzle as well as manifold innovation. MDi is a world-leading American manufacturer of Hot Runner systems and also parts with the capability to develop custom and innovative solutions for plastics Shot Molding.

Every one of our elements are internal developed and also manufactured in our facility at St. Charles, IL, with a focus on high quality as well as reliability.

When a mold and mildew opens, the product usually "drools" out because of pressure in the system. This could represent a significant amount of material lost with time, which can be expensive, particularly in high production tools. Use the Anti-Drool Sprue Bar Tool results in a more lasting, cleaner and also lower upkeep system lowering downtime as a result of clean-up.Learn Extra >.

An Unbiased View of Valve Gate Systems

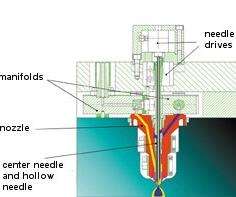

The i VG ™ carries out well under one of the most requiring handling problems. Unlike electrical shutoff gates and also standard pneumatically-driven cylinders, that can stop working in extremely hot operating settings, the interior shutoff entrance executes at temperature levels up to 400 ° C. Rheo-Pro ® i VG ™ internal valve gateway nozzles with a piston inside the nozzle body are clean, compact, as well as cooling-free.

Hot jogger mold VS 2 plate mold and mildew VS 3 plate mold Refers to the part between the mold and mildew inlet as well as the product gateway. The liquified plastic is kept flowing in the runner under the impact of the injection pressure and also its very own warm. The jogger only operates as component of the molding material, yet is not a component of the final product.

Valve Gate Systems for Dummies

The cold jogger has the ability to minimize the acrylate or polycarbonate used for light transmission in the shot mold jogger, so regarding prevent the noticeable strips triggered by the injection molding in some parts. Negative aspects of the cool runner: (1) More waste of basic materials; (2) Added steps in the entire manufacturing process; the cold runner mold and mildew include two series mold: two plate mold and mildew and 3 plate mold and mildew Two plate mold and mildew: When the mold and mildew opens up, the tooth cavity plate and the core plate are divided to release the molded item.

Being most extensively used, it is the easiest and also the majority of basic kind of the shot mold, and can be created as a single-cavity or a multi-cavity shot mold and mildew. Three plate mold and mildew 3 plate mold has 2 parting surfaces. Compared to 2 plate mold, it adds a partially movable intermediate plate (also called a movable runner plate, on which the gateway, jogger, along with other components and parts required for the core are designed) right into the dealt with mold and mildew fifty percent, so it is also recognized as a three-plate (tooth cavity plate, runner plate and also core plate) shot mold, which is typically made use of for the single-cavity or multi-cavity determine gate plastic injection mold.

The three plate mold includes a difficult structure, a high production cost, and also tough part handling, so generally it is not made use of for shot molding of big or extra huge plastic products As a typical part of the shot molding system, the hot runner ensures that the plastic product in the jogger and gateway keeps the liquified state by heating.

pop over here blog site here